Product Description

Turn Block™ Indexing Turn Table is the world’s most capable indexing turntable. This advanced turntable is capable of managing operator loading, robots, power, air, communication, and safety.

Features:

• No code integration.

• Control up to 8 stations with plug and play apps.

• Free user defined function blocks for custom app development.

• Select Program direction, speed, acceleration, deceleration, and # of positions.

• UL/CE horizontal control panel controls power, air, communication & safety.

• Touch Screen 7” HMI and PLC with Ethernet IP, Modbus, digital I/O, 0-10V analogue communications.

• Includes machine network switch, 24V power supply, safety relay, main/branch circuit breakers.

• Safety light curtains, door switches, part presence, and light tower plug and play with standard metric connections.

• Epson Robots are plug & play.

• SMC pneumatics are plug and play.

• Machine base expandable and reconfigurable with modular block structure.

• Process data capture

• Standard and custom table options from aluminum, steel, and engineering plastics.

• Bar code recipe selection

• Easily mount enclosures to directly to the block.

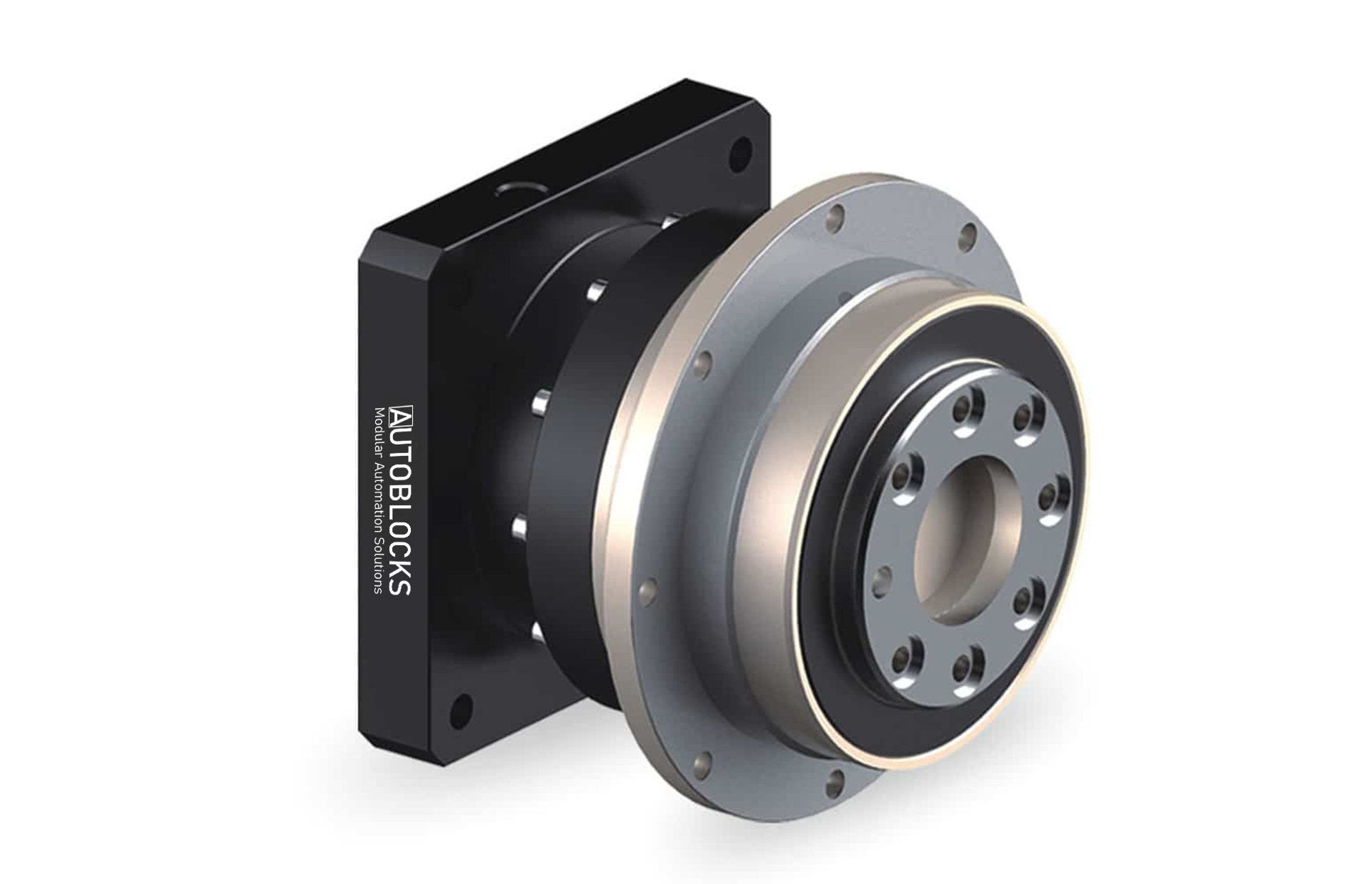

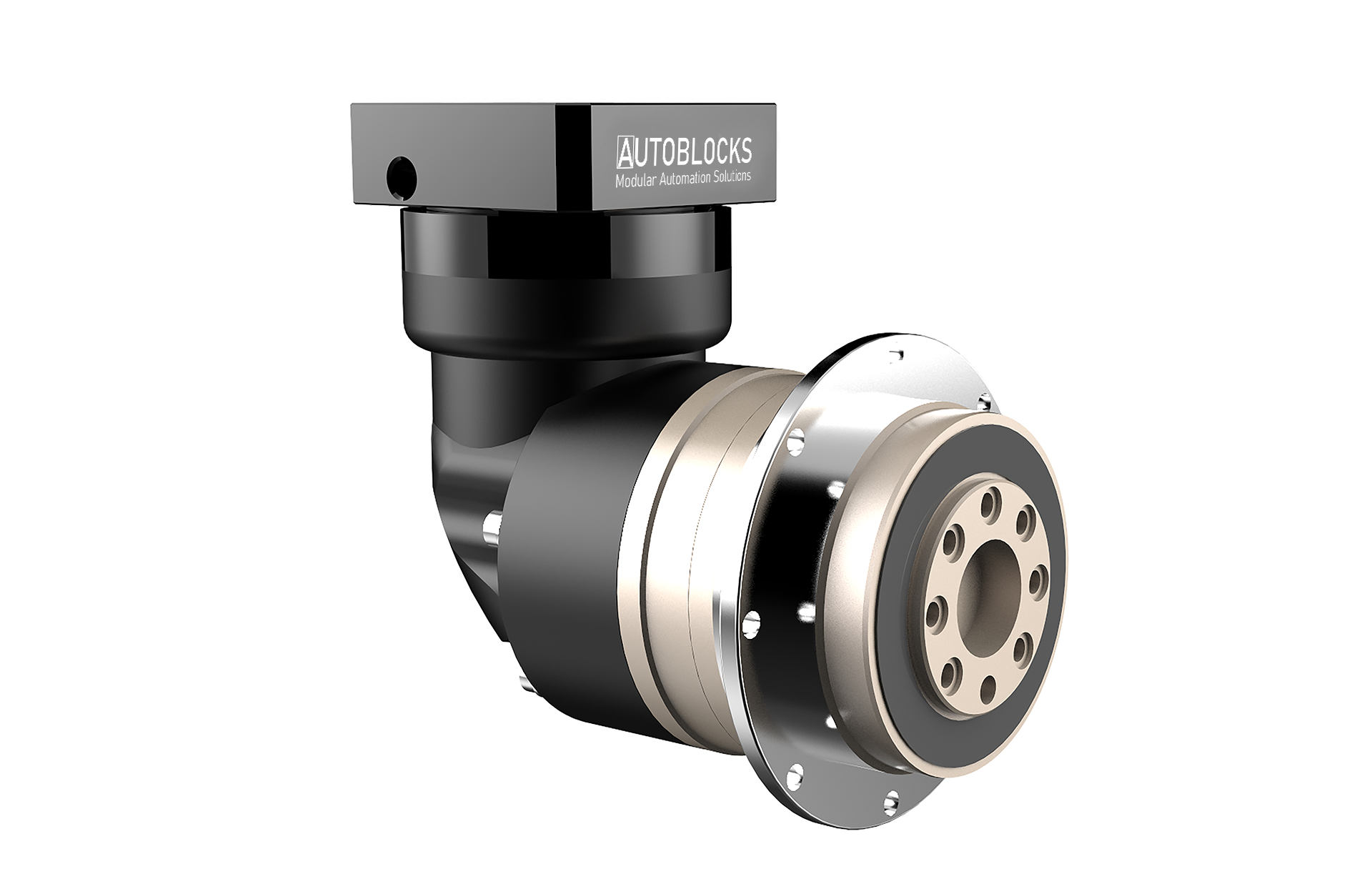

• Precision gear box options with 10, 5, 3 arc min backlash.

*Recommended for assembly automation of with two or more steps. Offers maximum flexibility with the ability to redeploy and scale with volume.

SPECIFICATIONS

General

Model: Turn Block 24

Table Diameter (sold separately): 24”

Size: 24W X 28”

Standard Repeatability: 5 Arc Min backlash maximum.

Optional Precision Repeatability: 3 Arc Min backlash maximum.

Direction: Counterclockwise

Indexing positions: 4 and 8

Approximate Size: 24” W x 28” D X 9” H

Approximate Weight: 125 lbs.

Electrical Power: 20 amps @ 240/1/60

Compressed Air: 80-100 PSIG

Speed & Torque

Max. Table Speed: 20 RPM

Max Torque at max speed: 5.4 in-lbs.

Enclosures (Sold Separately or provided by others)

Mounting: Light weight safety enclosure may be mounted table tapped holes.

Door Switches/Interlocks: Up to 4 door switches connect via daisy chain.

Part Presence: Part presence sensor is required for manual loaded systems.

Light Tower: Red/Green light tower quick connect is supported.

Light Curtain: Light curtain connection is provided for Keyence GL-S and GL-R series for plug and play with internal safety relay built in.

Mechanical

Structure: Interlocked steel base, pillars, and reinforced gear box support.

Mounting: Support pillars support other machine blocks w/ tool pin interlocks

Cover: Aluminum

Drive: Precision Gear box

Table Mount: ISO 9409-1 output flange

Max Symmetrical Unsupported load: 50 lbs.

Max Unbalanced/Unsupported load: 30 lbs.

Max Supported Load (additional rollers or support blocks required): 300+lbs

Table Materials: Acrylic, Aluminum, Steel, Engineered Plastics.

Main Air Supply: 16 mm

Station Air supply Lines: 12 mm

Electrical

Electrical Power: 20 amps @ 240/1/60

SCCR Rating: 10 kA rms SYMM, 240V MAX

Environment Rating: TYPE 1

Light Curtains: (2) Quick connects for receiver and transmitter.

Door Switches: (1) Quick connect for door sensor circuit.

Part Presence Sensor: (1) Quick connect for door sensor circuit.

Light Tower: (1) Quick connect for red/green light tower. Station Power: (3) 240V single phase 6 A power circuits for each station. Max

FLA 7.5A

Station E-Stop: Each station is prewired for 24V safety circuit.

Communication

Station Digital Outputs: 3 (9 total)

Station Digital Inputs: 5 (15 total)

Analogue Output: (1) 0-10V (3 total)

Communication Protocol: Modbus TCP (4 RJ45 ports)

Bar Code: Prewired for (1) USB type A Bar Code Scanner

Controls

HMI: 7” Resistive Touch Screen PLC

Safety Relay: Built in & prewired for light curtain and door switches.

Circuit Breakers: Internal main, station and motor breakers.

Main Disconnect: Lockable power disconnect on front of machine.

Low Voltage Power Supplies: Built in 24 V and 5 V power supplies.

Homing Sensor: Built in induction homing sensor.

Station Control: 3 dedicated & 1 auxiliary.

Accessories: Controlled by Robots or PLC directly

Robots: Up to 3 simultaneous controlled.

Vision Systems: Controlled by Robot or PLC directly.

Software

Programming Specifications: IEC 61131-3

Warranty: 12 months against manufactured defects not including labor.

Turn Block Manual

Turn Block Manual