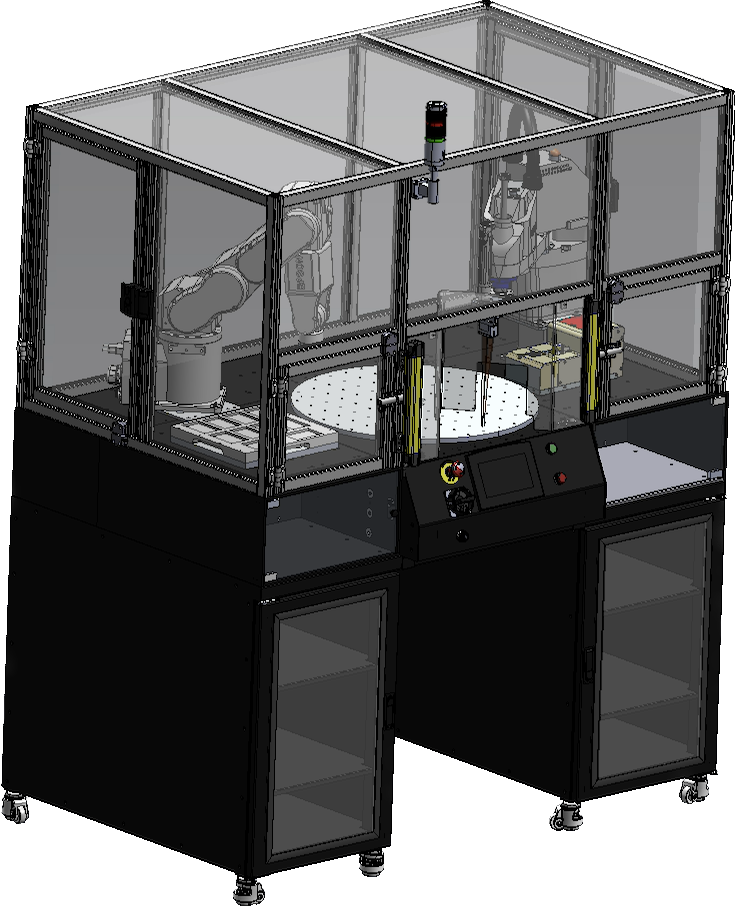

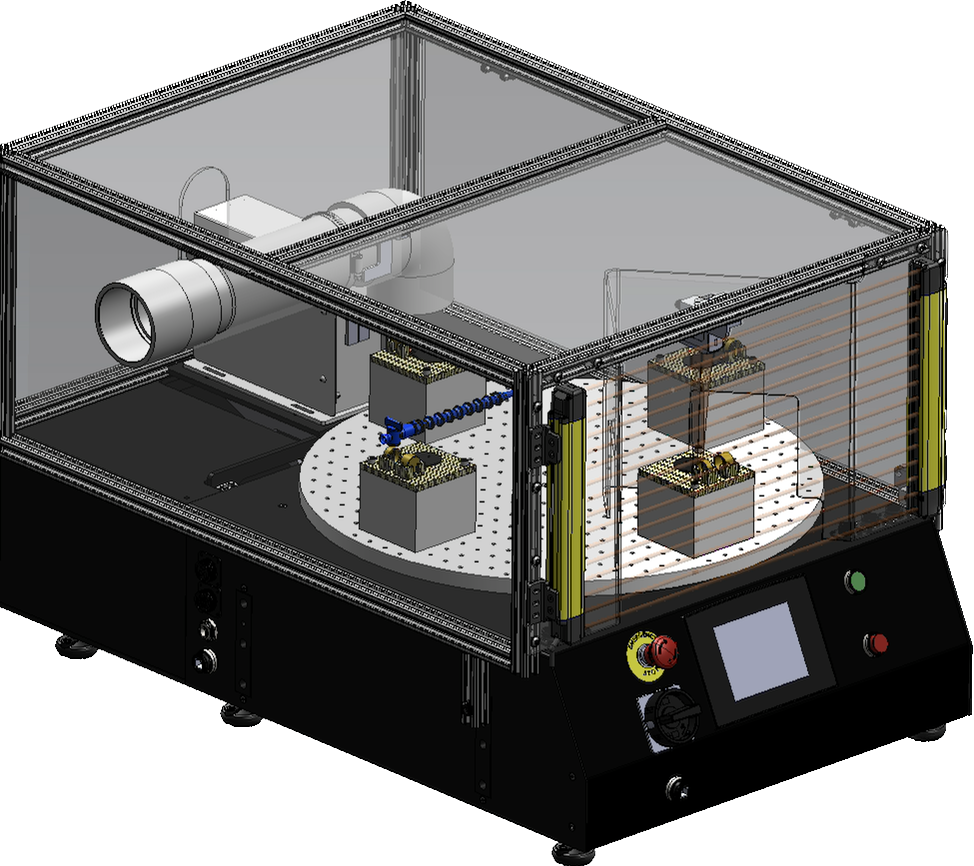

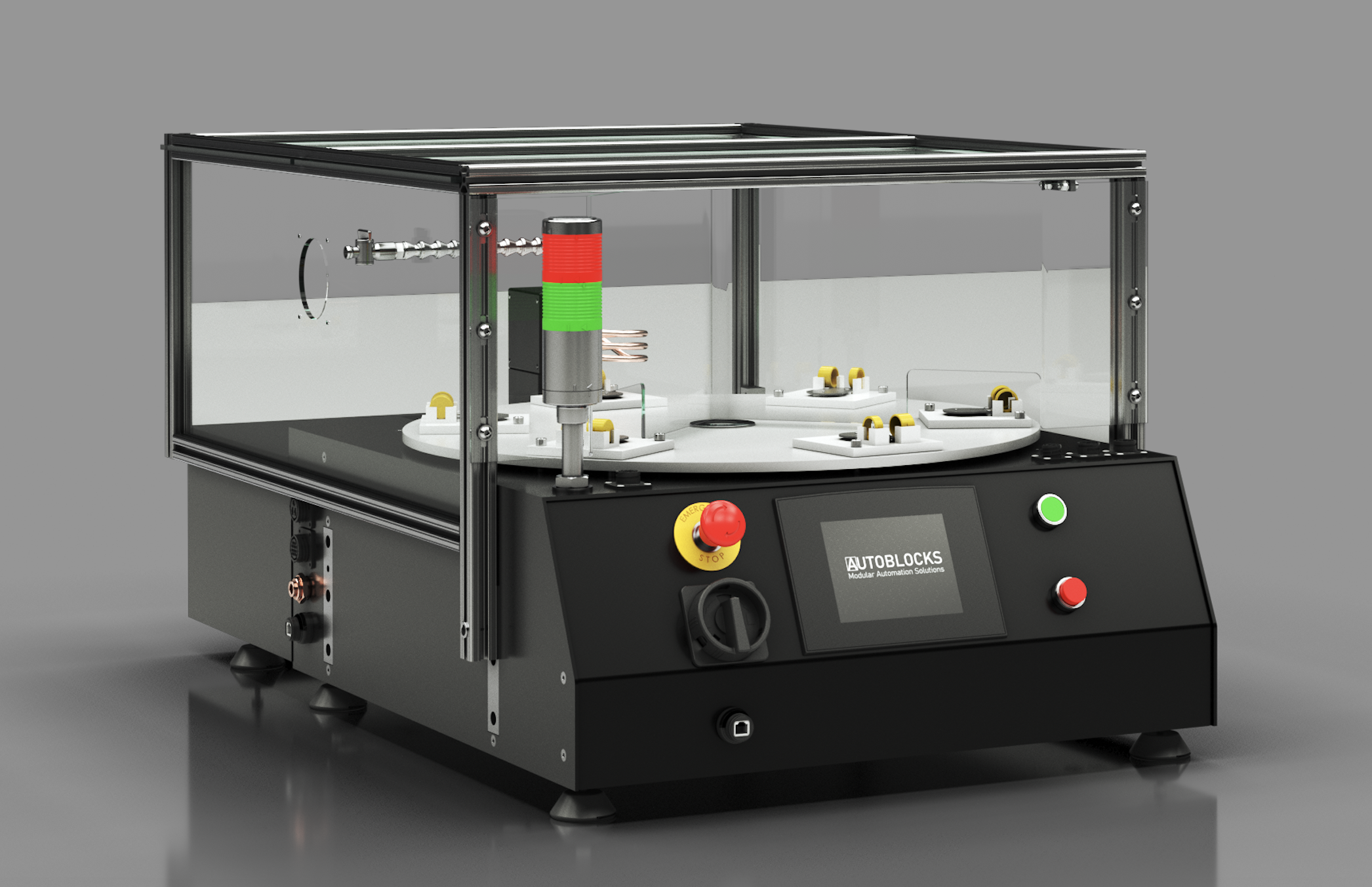

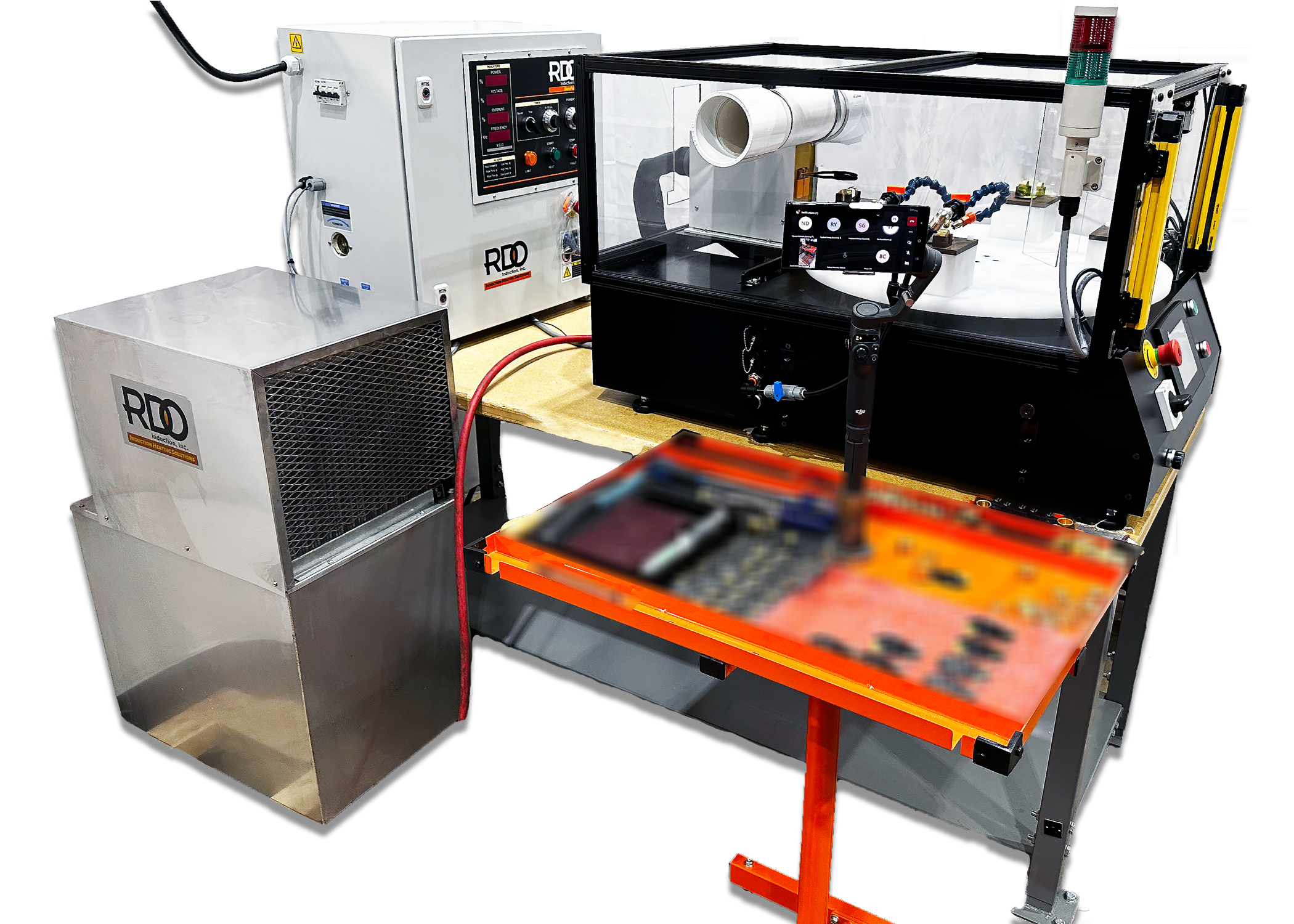

Overview

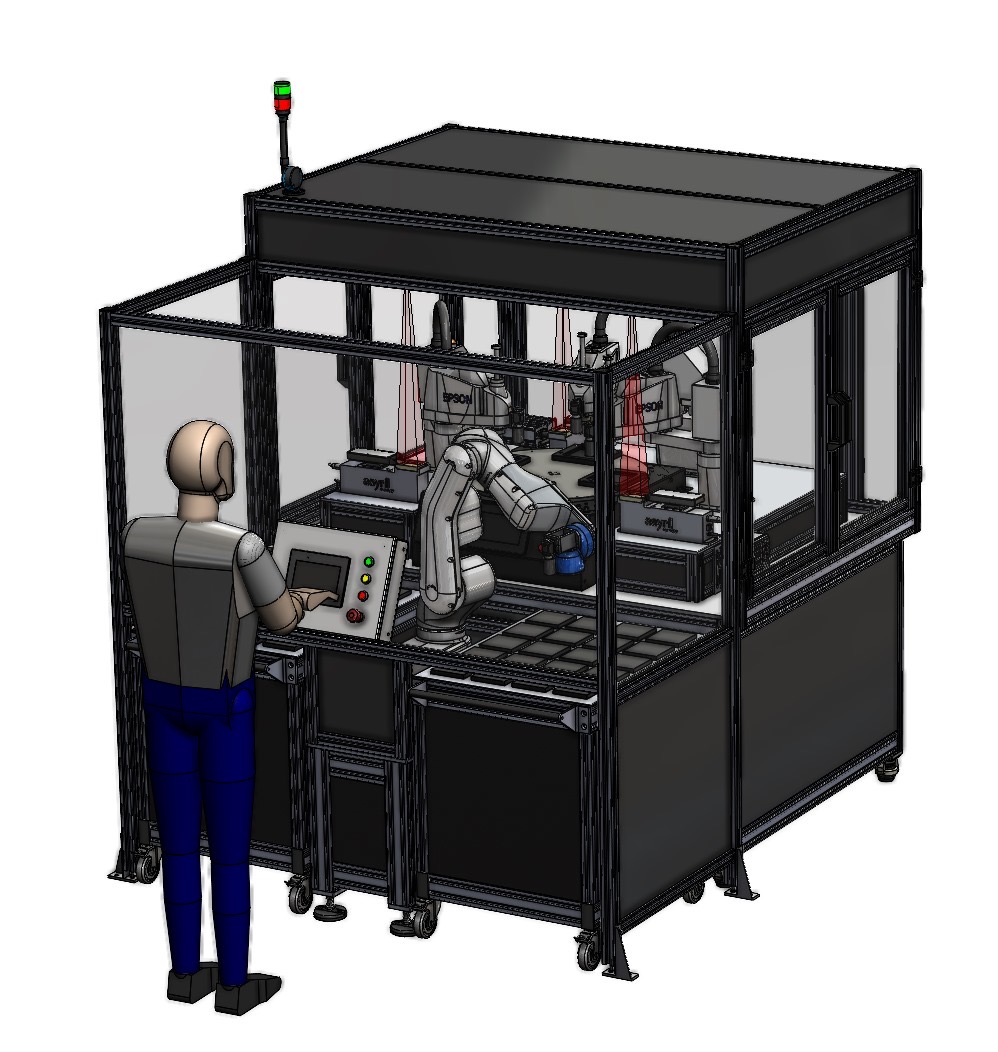

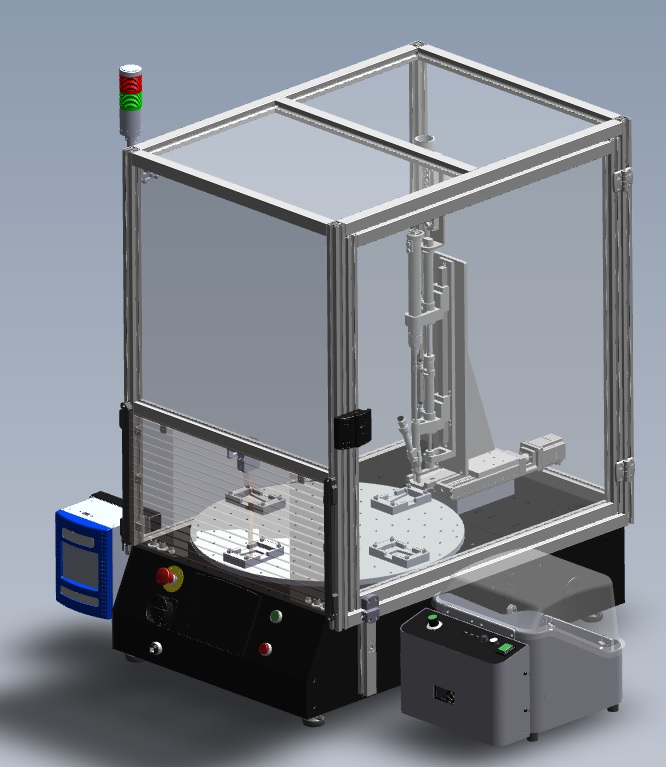

Welcome to our Use Case Gallery, where we present a collection of assembly machines built by AutoBlocks™️. Through images and detailed descriptions, we invite you to explore a variety of innovative systems designed and built using our standardized and modular approach. These Turn Block™ and Machine Block™ based solutions demonstrate how AutoBlocks™️ revolutionizes custom machine building, offering cost-efficient modules and easy-to-use software for accelerated deployment, reduced costs, and increased productivity. Immerse yourself in this showcase and witness the transformative power of AutoBlocks™️ in driving next-generation assembly machines.