Control Block

Unlock Your Offer: $0.00

Configuration costs: -

Autoblocks Control Block: The Ultimate Machine Controller

Overview:

The Autoblocks Control Block is a powerful, all-in-one solution for industrial automation, designed to control complex machinery with ease and flexibility. Equipped with advanced motion control, integrated safety features, seamless communication capabilities, and the ability to run two software programs, the Control Block empowers machine builders, integrators, and manufacturers to streamline production with precision and efficiency.

• Precision assembly

• Robotics control

• Industrial automation

• Custom machine design

Ready for the Future:

With its no-code, plug-and-play architecture, the Autoblocks Control Block is built for the next generation of automated systems. Control your entire production line with ease, reduce downtime, and scale effortlessly.

Product Description

Key Features:

• Comprehensive Motion Control: Supports up to 6 axes of coordinated motion, including gantry and SCARA robots, with the ability to daisy-chain additional motors. Ideal for precision assembly, this flexible system can handle NEMA 8 to NEMA 34 motors with built-in brakes and absolute encoders for advanced motion tracking.

• Integrated Safety and Logic: The Control Block is equipped with a built-in Keyence safety controller, ensuring compliance with industrial safety standards while maintaining reliable and consistent machine operation. It also features 8 digital inputs, 8 6A relay outputs, and a dedicated safety circuit output for enhanced safety management.

• Expandable and Customizable: The modular design allows for simple expansion using remote I/O, enabling easy integration of additional devices. The system supports up to six motors via M12 cables and can easily scale with your production needs.

• Plug-and-Play Simplicity: Designed for fast and efficient setup, the Control Block features a user-friendly interface powered by AutoCode —a table-based programming environment. AutoCode simplifies machine programming, enabling operators to create or modify machine sequences with minimal coding experience. The Control Block supports plug-and-play integration of light curtains, light towers, door interlocks, and more.

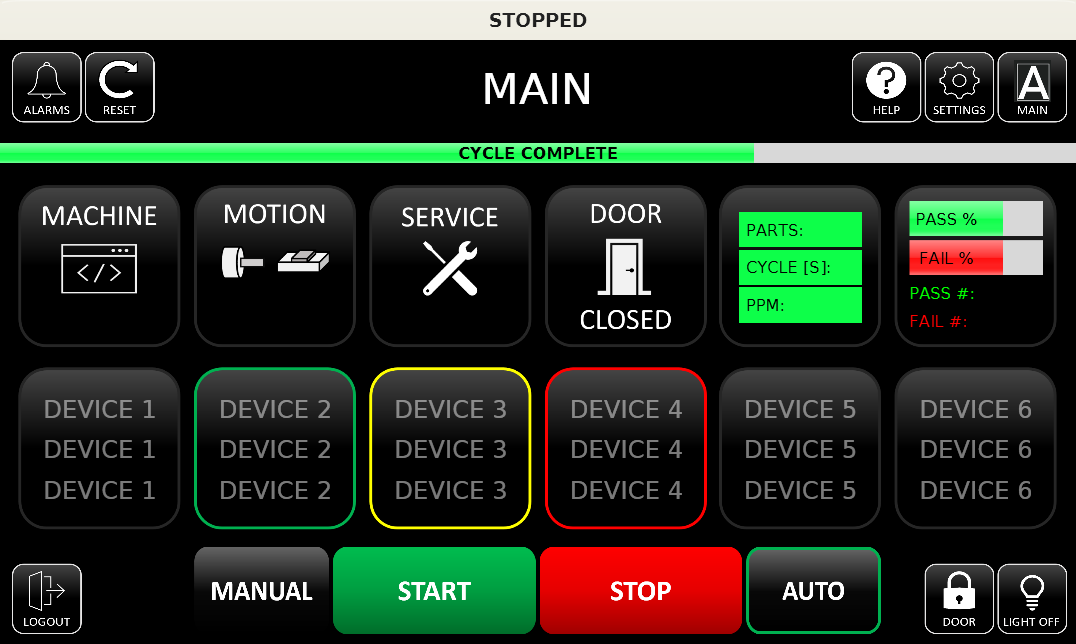

• Unified Control Panel: Connect and manage up to 6 devices through a single interface, with real-time status updates and direct access to device settings, recipes, and AutoCode logic. The unified platform offers enhanced support for diverse applications, from assembly lines to CNC operations.

• Data Tracking and Error Handling: The Control Block features advanced data tracking, comprehensive error handling, and recipe management to ensure smooth, reliable operations, and quick recovery from any issues.

• Optimized for Industrial Use: The Control Block fits within standard server rack dimensions and includes front ventilation for efficient cooling. Built for durability, it is engineered to withstand the demands of modern industrial environments.

Whether you’re automating a precision assembly process or managing a complex robotic system, the Autoblocks Control Block delivers unmatched flexibility, performance, and ease of use, making it the ultimate machine controller for integrators and machine builders.

Technical Specification Sheet Overview The Autoblocks Control Block is a robust and unified machine controller that effortlessly combines logic, safety, and motion control into a single, streamlined platform. It supports up to 6 axes of plug-and-play single-cable motion, engineered specifically for precision assembly applications. Offering no-code integration, it simplifies the management of diverse industrial robots, vision systems, safety devices, and sensors, making it accessible even for those with limited programming experience. Its modular, flexible design allows for seamless scalability, from small batch processes to fully automated production lines, making it the perfect solution for a wide range of industrial automation requirements. Additionally, the Autoblocks platform includes the AB+ product line, offering highly compatible motors, actuators, and gearboxes that further enhance system versatility and expand automation capabilities across multiple applications.

Hardware Specifications

Form Factor

• Dimensions: 24” L x 20” W x 8” H

• Weight: ~25 lbs.

• Mounting Options: Optional Mounting Brackets

• Ventilation: Front fan exhaust design with rear and side filtered inlets.

• Chassis: Industrial-grade aluminum with black anodized finish.

• Ingress Protection: IP54 rated enclosure, suitable for dust-protected environments.

Power Supply

• Voltage Input: 110-126 VDC

• Amperage Input: Max 15A

• Motor Power Output: 24 VDC/4A per motor (up to 6 motors)/576W

• 24V Bus (8 terminals) Power Output: 7A Max/168W

• 0V Bus (8) terminals

• POE Port Power Output: POE+/IEEE 802.3at/25.5W per port/90W total

• Total Power Output Capacity: 834W

• Protection: Overvoltage, short circuit, and reverse polarity protection.

Connectivity Motor Interfaces:

• Supports NEMA 8, 10, 17, 23, 34 absolute encoder closed-loop stepper motors

• Single M12 cables with absolute encoders for all motor connections

• Programmable brakes available in all sizes (no separate wiring).

• Home-run architecture from PLC to motor (6 motors supported natively)

External Ports:

• (3) External RJ45 PoE+ (Power over Ethernet) Ports

• 10/100/1000BASE-T

• IEEE 802.3at POE

• (1) USB 2.0 for file management

• (1) DB15 for HMI teach pendant/HMI with integrated e-stop circuit.

• (1) M12/4 PIN remote e-stop port

• (1) M12 light curtain transmitter

• (1) M12 light curtain receiver

• (1) M12/4 PIN for 3 color light tower.

• (1) M12 door interlock port for daisy chaining up to 8 interlocks.

Communication Protocols:

• Ethernet/IP

• MODBUS TCP

• CANopen/CANLayer2

• RS485

• RS232

• EtherCAT Master (optional)

• MQTT Client

• SNMP

• Message Composer for custom protocols

I/O:

• 8 digital inputs (expandable)

• 8 relay outputs (expandable)

• Quick Push connect terminals

• I/O Link Expandable with master and hubs

• Expandable up to 2048 I/O

Other:

• SQL Client

• WEB Server

• E-Mail & SMS

• VNC

• FTP server/client

• GPRS

Safety Features

• Safety Controller: Integrated Programmable Safety Controller

• Ple, Category 4, SIL3 Safety Standards

• Plug and play safety devices – light curtain, door interlocks, remote E-stop, light tower, and other safety devices

• Customizable programming

• Safety event tracking

• Remote Emergency Stop Circuit: Remote E-stop port to connect field devices.

• Interlocks: Plug and play magnetic door interlock/switches. HMI password controlled.

Mechanical and Environmental Specifications

• Operating Temperature: 0°C to 40°C

• Storage Temperature: -20°C to 70°C

• Humidity: 10% to 90% (non-condensing)

Software & Control Capabilities

Software Packages:

• Control Block comes pre-loaded with choice of AutoCode or TurnCode.

• AutoCode – software package for generalized automation control

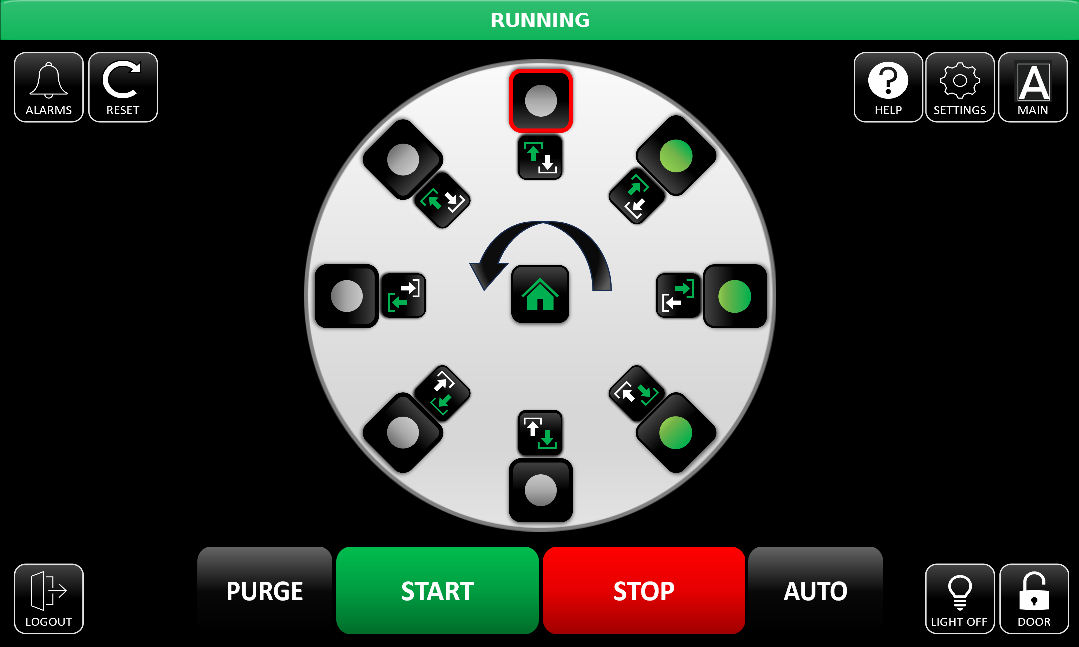

• TurnCode – software package specializing in modular rotary control

• Custom Interfaces – Limited custom Interfaces are available with NRE.

AutoCode Programming Environment:

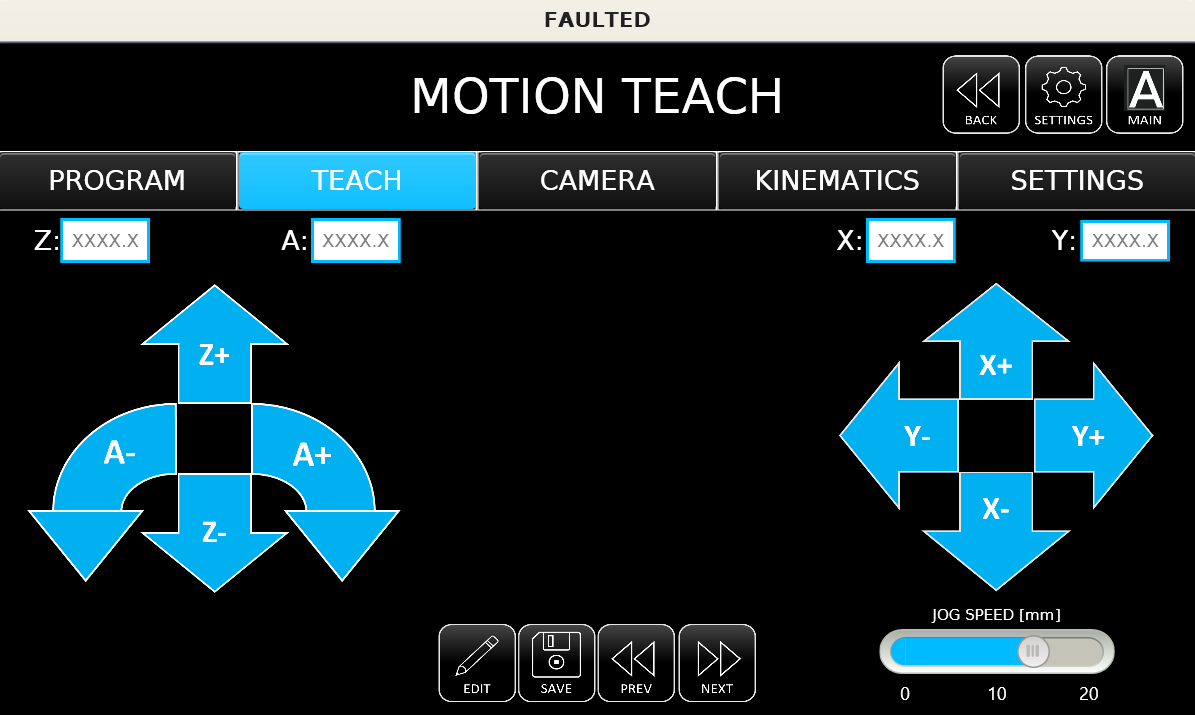

• Table-based command structure compatible with PLC and CAM programming

• Supports custom commands and developer environment.

• Supports AI-generated AutoCode for fast programming

• Multi-axis motion control with minimal user input required for machine setup

• G-code Compatibility: Can import and execute G-code for robot and CNC operation.

• Recipe Programming: Integrated recipe management for production line reconfiguration

• Machine Master and up to (6) Slave device AutoCode control.

HMI/Teach Pendant Interface:

• 10.1- inch high resolution capacitive touch screen HMI interface.

• Supports flipping between HMI and other web interfaces.

• Optional HMI interface module available to support third party Touch Screens.

• Integrated E-Stop

• USB 2.0 Port for file management

• Supports VNC/Remote connectivity

• Supports Bluetooth and Wi-Fi connectivity

HMI HUB Interface:

For customers who prefer to use their own touchscreen monitors and peripherals like a keyboard and mouse, Autoblocks offers a pre-configured hub interface. This plug-andplay solution comes preloaded with our HMI software and allows any 1280×800 touch monitor to connect via a single standard HDMI and USB cable. Seamlessly integrating with the Control Block, the hub ensures a smooth, hassle-free setup, with all necessary cabling included for easy connection. E-stop must be added separately via the DB15 or remote e-stop connectors.

Motion Control

Axes Control:

• 6 primary axis of control (X,Y,Z,A,B,C)

• 4 axis teach control

• Simplified wiring via M12 cables for power and communication.

• High-precision motion with closed-loop control using absolute encoders

• Real-time trajectory planning with coordinated motion control

Safety and Error Handling

• Built-in Fault Detection

• Diagnostic system with real-time error logging

• Automatic motor shutdown in case of fault

• Red, Green, and Yellow HMI/light tower status indicators

System Integration Modularity:

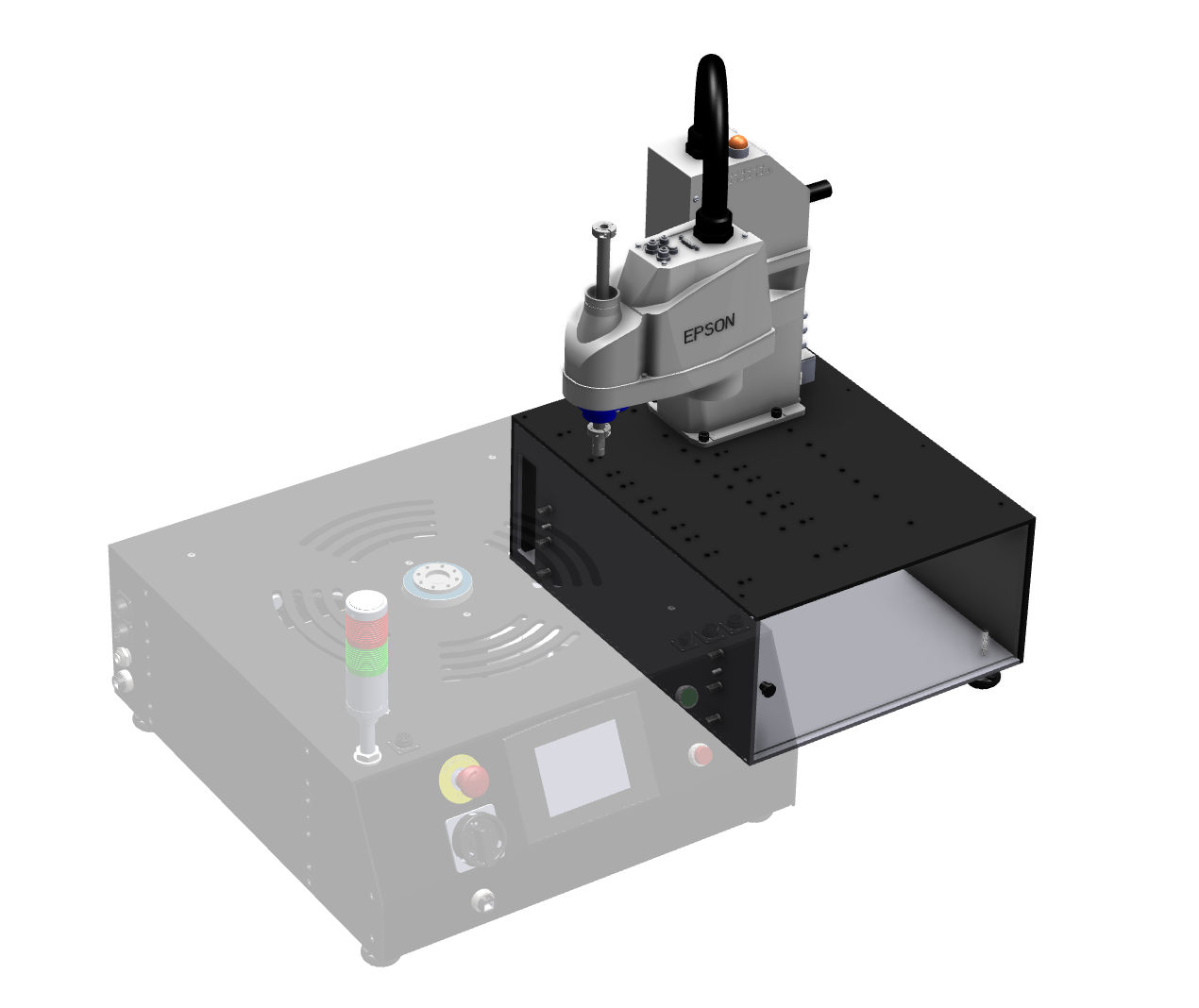

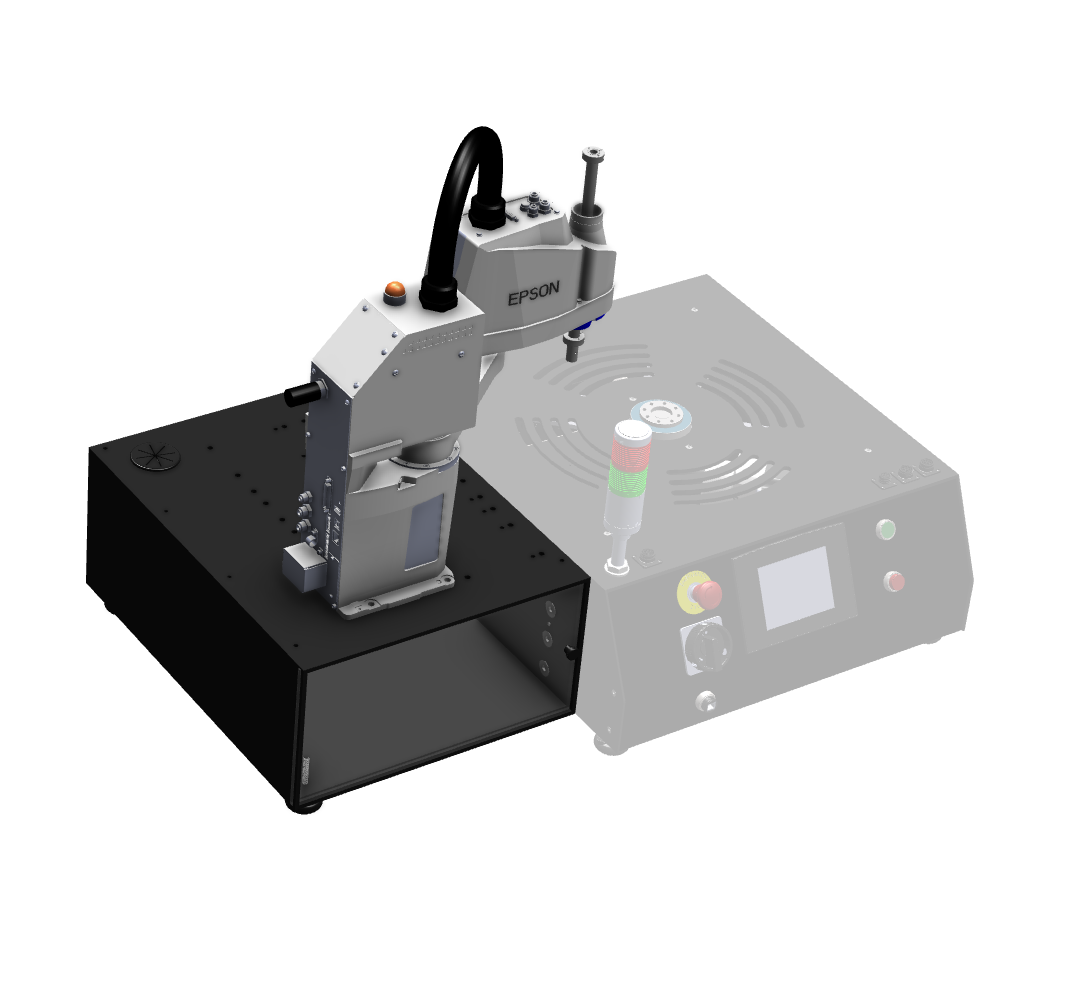

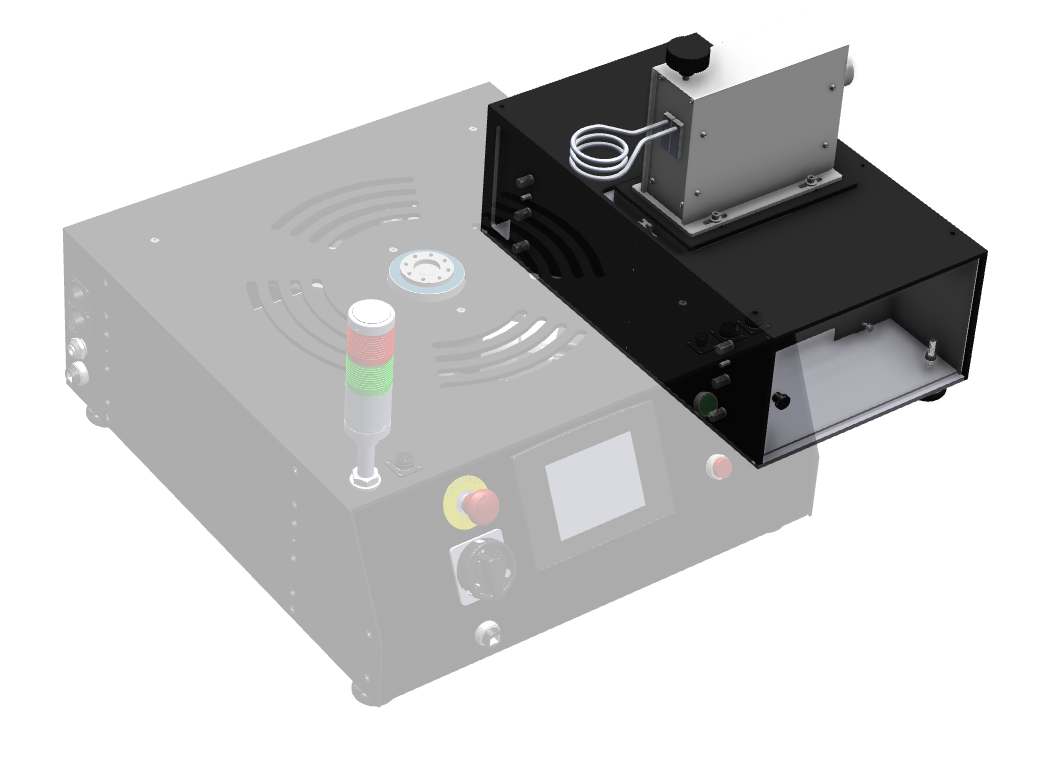

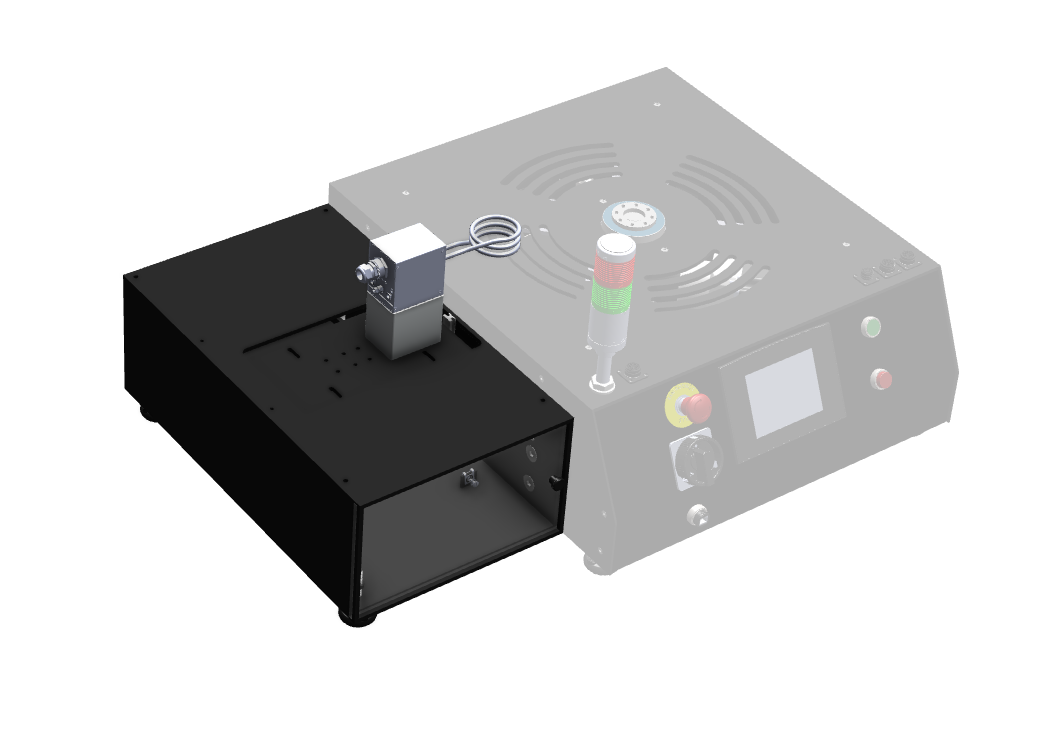

• Compatible with both gantry and SCARA robots using the same distributed motion platform

• Flexible device integration through Auto-code or PLC programming for complex machine control

• Expandable I/O and motor controls for future scalability

Supported Devices AutoBlocks Smart Motors:

• NEMA 8, 10, 17, 23, 34

• Closed-loop stepper motors with absolute encoders

AutoBlocks Smart Actuators:

• Precision Ball Screw Actuators +/- 0.005mm up to 2000mm

• Belt Drive Actuators +/- 0.05mm up to 3000mm

• Customizable Cartesian Gantries available.

AutoBlocks Precision Planetary Gear Boxes:

EPSON Robots:

• EPSON Robots are plug & play with simple device selection on the HMI.

• EPSON robot program templates with extensive handshake and error handling prebuilt.

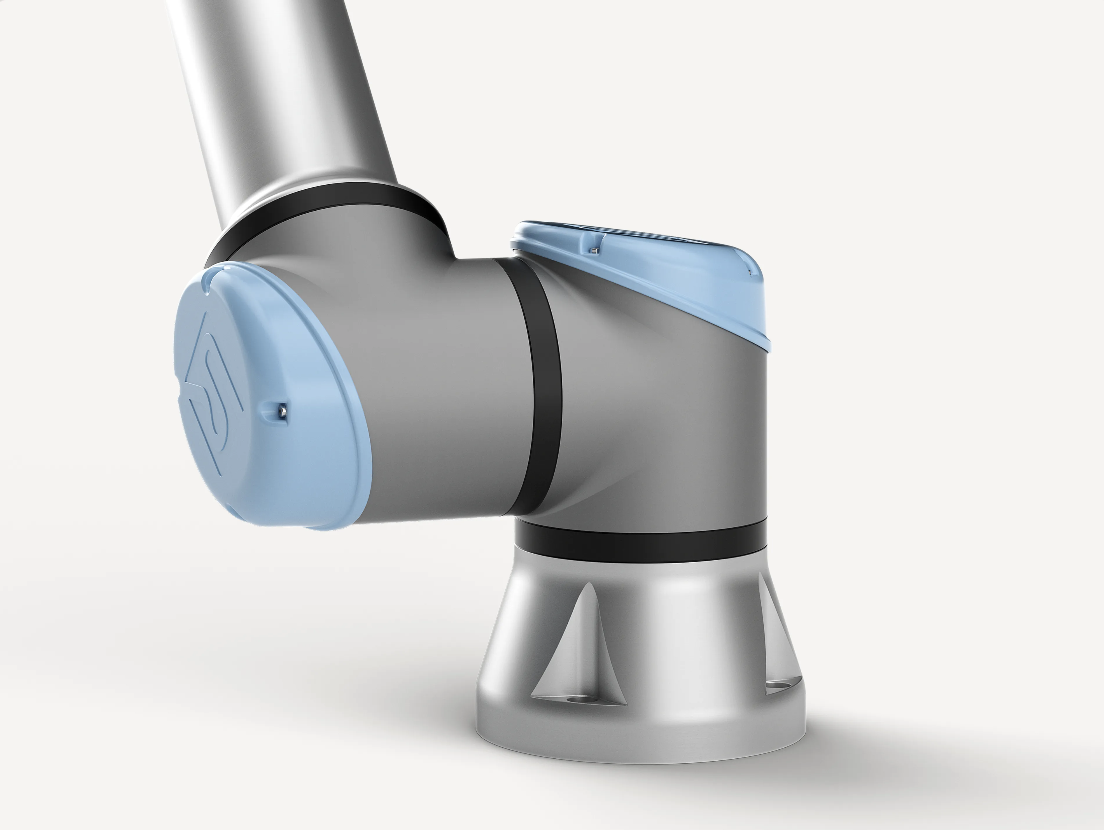

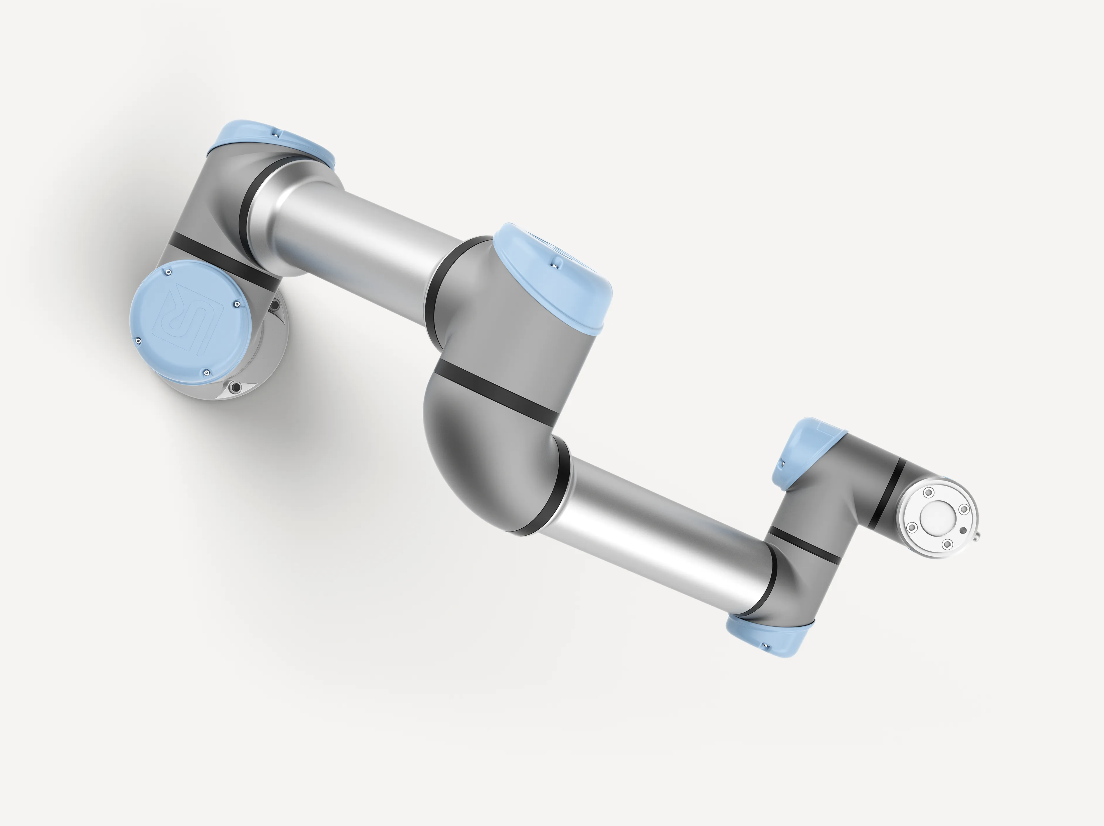

Universal Robots:

• UR robots are plug & play with simple device selection on the HMI.

• UR CAPP with extensive handshake and error handling prebuilt.

Vision Systems:

• Keyence IV3/4

• Keyence VS

• Zebra FS/VS

• Cognex

Custom devices supported Servo Drives & VFDs:

• AutoBlocks Smart Servo Drives & VFDs come plug & Play

• Third Party Servo Drives & VFDs available.

Safety:

• Keyence GS Door interlocks

• Keyence Light Curtains

• Banner Light Towers

• Custom devices supported Cloud

• Customizable Cloud Machine monitoring dashboard

• Remote Support

• Remote Software Customization and Support.

Other Devices:

• Control Block is simple to configure for any discrete I/O device

• High level communication devices are simple to add with NRE or development.

Integrator Support The Autoblocks Control Block is targeted at integrators and machine builders seeking a cost-effective, highly configurable, and easy-to-program machine controller. Its plugand-play capabilities and AI-driven AutoCode functionality reduce the need for extensive programming, making it ideal for medium complexity machines in industries such as automotive, electronics, medical devices, and precision assembly.

Ordering Information

This technical specification sheet provides a detailed overview of the capabilities and components of the Autoblocks Control Block, highlighting its advanced features for motion control, machine safety, and flexibility in industrial automation applications.

Autoblocks Control Block Spec Sheet

Autoblocks Control Block Spec Sheet