Autoblocks Software Overview

Autoblocks offers a cutting-edge software suite designed to simplify the control of industrial machines, robots, and automation systems. At its core, the Autoblocks software consists of two distinct programming environments: AutoCode and TurnCode. These platforms provide a streamlined, no-code approach to motion control, logic programming, and system management, ensuring ease of use for machine builders and integrators without requiring extensive programming knowledge.

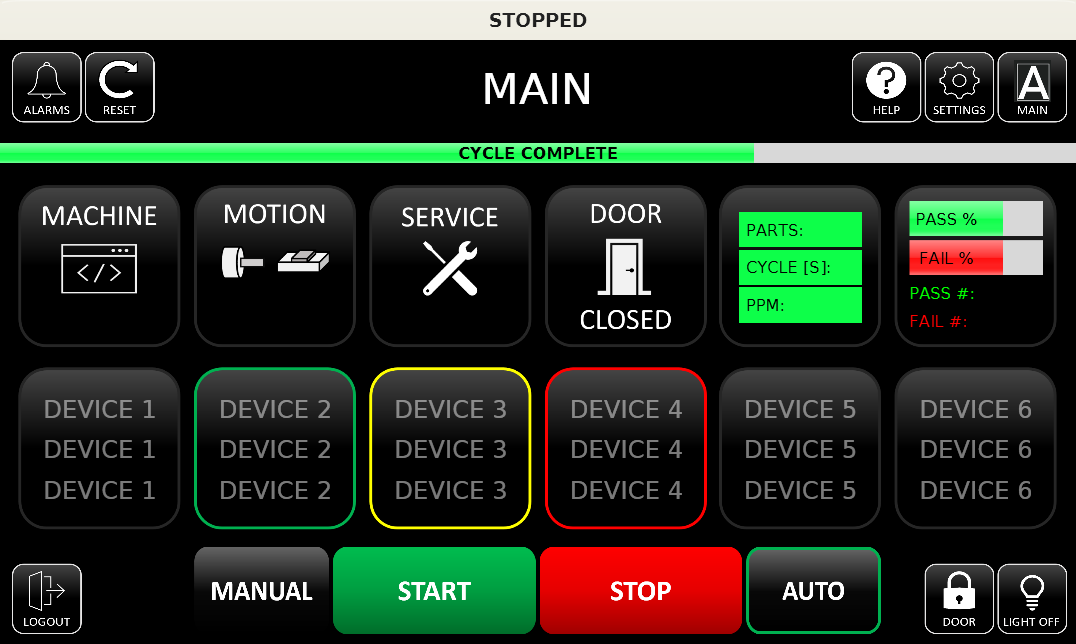

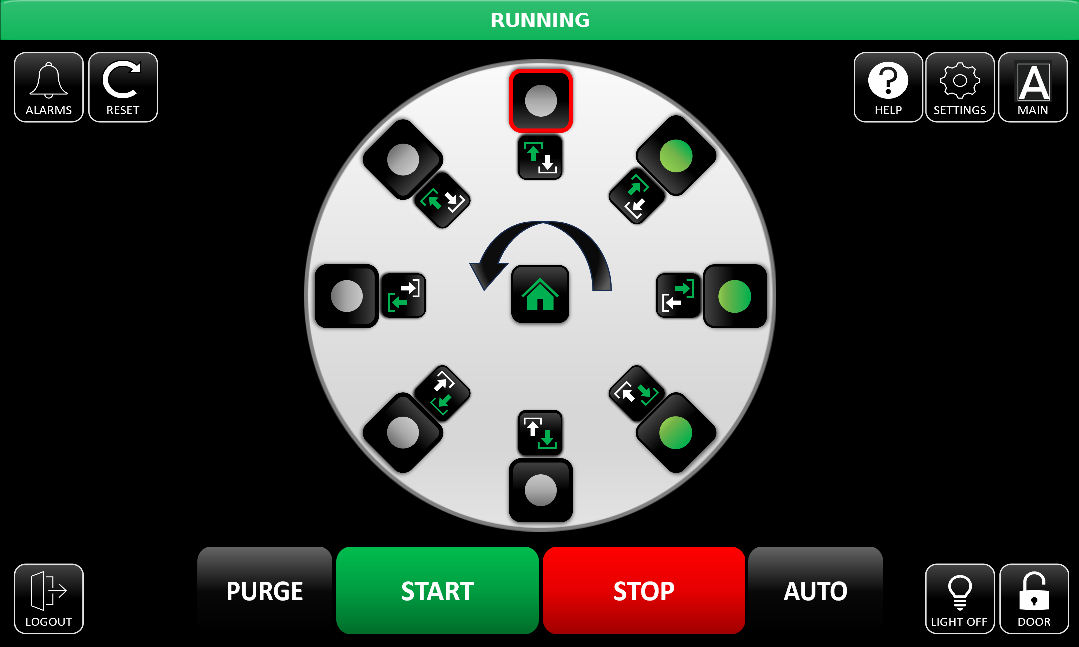

The Autoblocks software integrates with the Autoblocks Control Block to offer plug-and-play functionality for various devices, such as motors, actuators, sensors, and safety systems. With intuitive interfaces and powerful programming options, Autoblocks delivers a comprehensive solution for automation systems ranging from small batch operations to full-scale production lines.

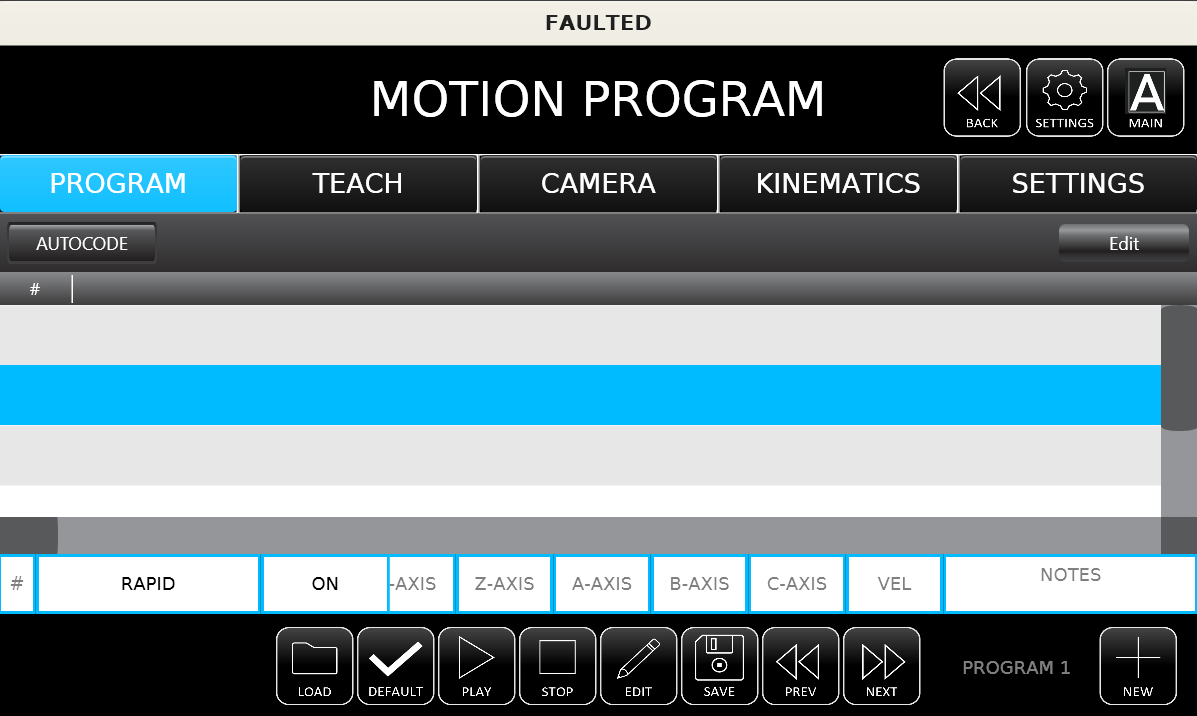

AutoCode

AutoCode is a universal programming environment designed to handle linear systems, gantry robots, and more complex production lines. It is ideal for applications requiring precise control over multiple devices in a coordinated manner. AutoCode emphasizes simplicity and efficiency, allowing users to configure devices and their operations through a straightforward table-based programming system.

Key Features:

Multi-Axis Motion Control: AutoCode supports up to 6 axes of motion, making it suitable for complex automation setups such as gantry robots or conveyor systems.

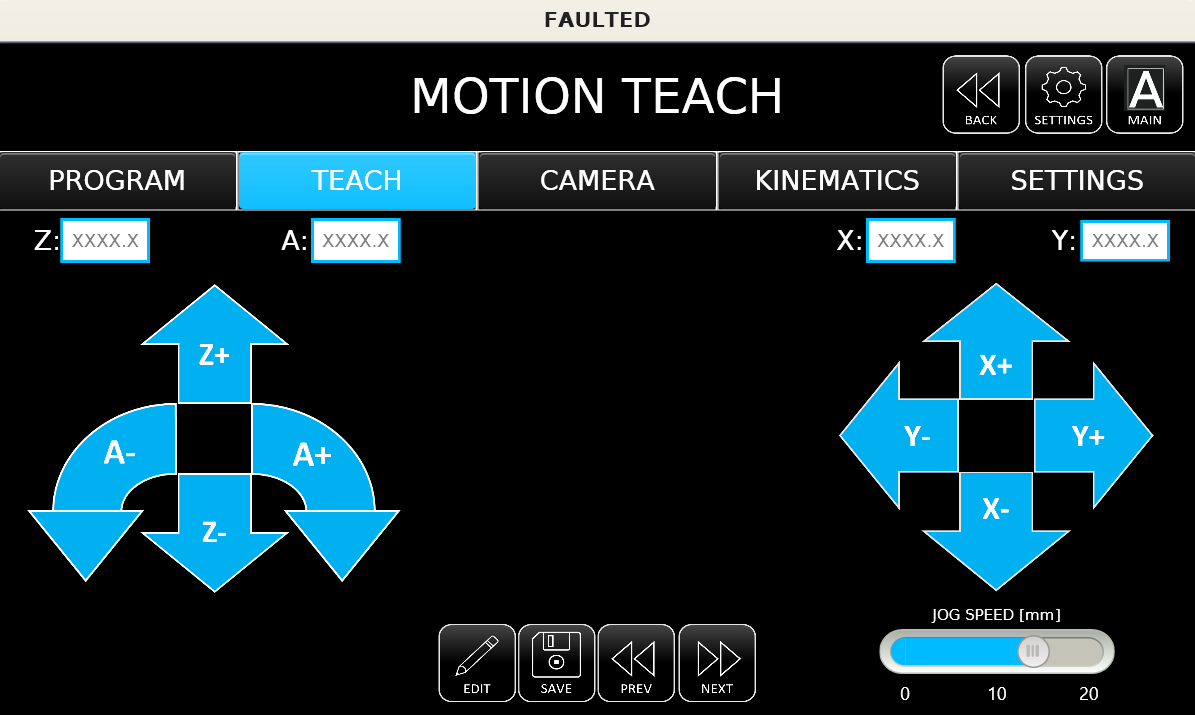

Jog and teach motion: Jog and teach robotic motion with intuitive touch screen teach pendent

Offline Simulation and CAM Programming: Simulate and write complex motion profiles using FUSION 360.

Device Management: The software allows for the seamless configuration of various devices, such as motors, actuators, and sensors, within a unified system.

Table-Based Programming: AutoCode uses a tabular programming format where each device and function is represented by rows in a table. This structure simplifies programming and reduces the likelihood of errors.

Peripheral Control: In addition to managing motion, AutoCode enables precise control over peripheral devices, ensuring synchronization between motion and other system components.

No-Code Interface: Designed to eliminate the need for traditional coding, AutoCode empowers users with little programming experience to develop complex machine programs quickly.

Use Cases:

AutoCode is best suited for linear systems and gantries in industries such as electronics assembly, medical device manufacturing, and small-batch production environments. It provides an efficient way to control precise, multi-axis movements while integrating sensors and peripherals.